What Are Vibratory Feeders and How Do They Work?

In the world of manufacturing and automation, efficiency and precision are key to maintaining productivity and quality. Among the essential components that help achieve these goals is the vibratory feeder, a type of bulk material handling equipment. Commonly used across multiple industries, vibratory feeders support the automation of production lines by delivering materials in a consistent and controlled manner. This article examines the operation of vibratory feeders and highlights their significance within the broader context of industrial automation.

Exploring the Function of Vibratory Feeders in Manufacturing

Vibratory feeders are essential bulk material handling equipment designed to efficiently and consistently transport controlled streams of materials through different manufacturing stages. Using vibrations, they guide materials along a designated path, ensuring precise positioning for subsequent production or packaging processes. This controlled movement is vital for maintaining a steady workflow and minimizing bottlenecks on the production line. By automating the material feeding process, vibratory feeders help streamline operations and boost overall productivity.

Identifying Industry Applications for Vibratory Feeders

As a type of bulk material handling equipment, vibratory feeders are designed to manage a wide variety of materials, including powders, granules, and small components. Their adaptability makes them indispensable in industries such as pharmaceuticals, where accurate dosing is crucial, and in food processing, where cleanliness and consistency are paramount. In the automotive industry, they play a vital role in efficiently feeding parts such as fasteners and clips along the assembly line.

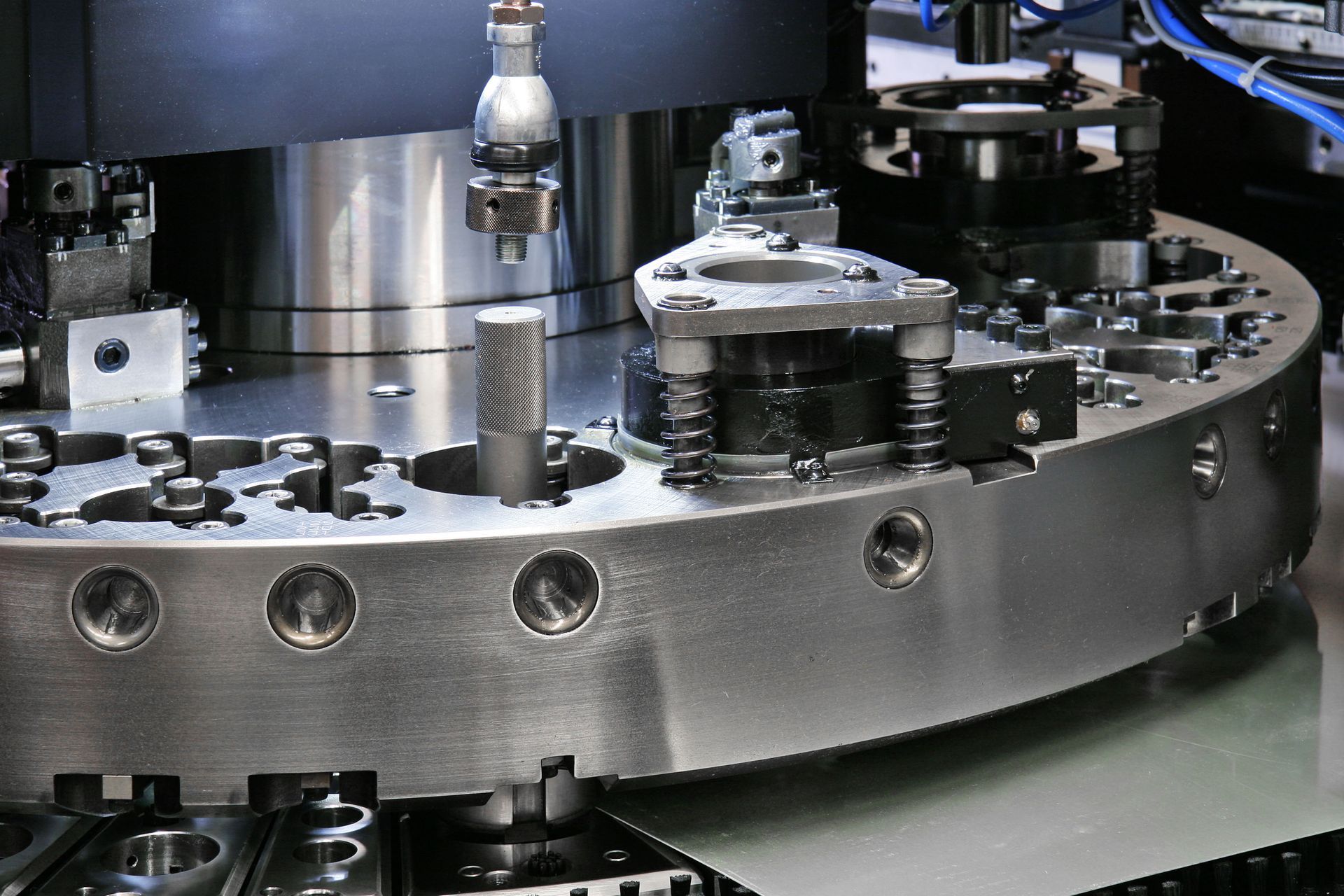

Understanding the Components of Vibratory Feeder Systems

The operation of vibratory feeders depends on two essential components: the feeder tray and a drive system, which can be either electromagnetic or mechanical. The feeder tray serves as the surface where materials are loaded before being transported. Positioned beneath the tray, the drive system generates consistent vibrations that move the materials along a predetermined path. This vibration-based movement helps align and space the materials properly, preparing them for the next stage in the production process.

Adjusting Frequency and Amplitude for Precise Material Flow

One of the key advantages of vibratory feeders, a type of bulk material handling equipment, is their adjustable frequency and amplitude settings. These customizable controls enable operators to regulate the intensity and speed of material flow precisely, matching the specific needs of the application. Such precision is essential for maintaining consistent output while preventing overflows or slowdowns on the production line. By ensuring smooth and continuous material movement, vibratory feeders enhance overall manufacturing efficiency and support higher product quality.

Highlighting the Efficiency Benefits of Vibratory Feeders

One of the most significant advantages of vibratory feeders is their ability to handle and manage material flow with minimal human intervention. Compared to manual feeding processes, vibratory feeders reduce the risk of human error, thus enhancing the overall efficiency and reliability of production lines. These systems also ensure consistent feeding rates, which can be particularly important for sensitive manufacturing processes that require precise material doses.

Examining Market Growth for Vibratory Feeder Technology

The market for vibratory feeders has seen steady growth, a trend attributed to the increasing automation of industrial processes. According to BusinessResearchInsights.com, the global vibratory bowl feeder market size is $160 million in 2024 and is expected to reach $125 million by 2032. This growth highlights the increasing demand for reliable and efficient material handling solutions as industries strive for greater automation levels. With their robust construction and ability to handle a wide range of materials, vibratory feeders are well-positioned to meet this demand.

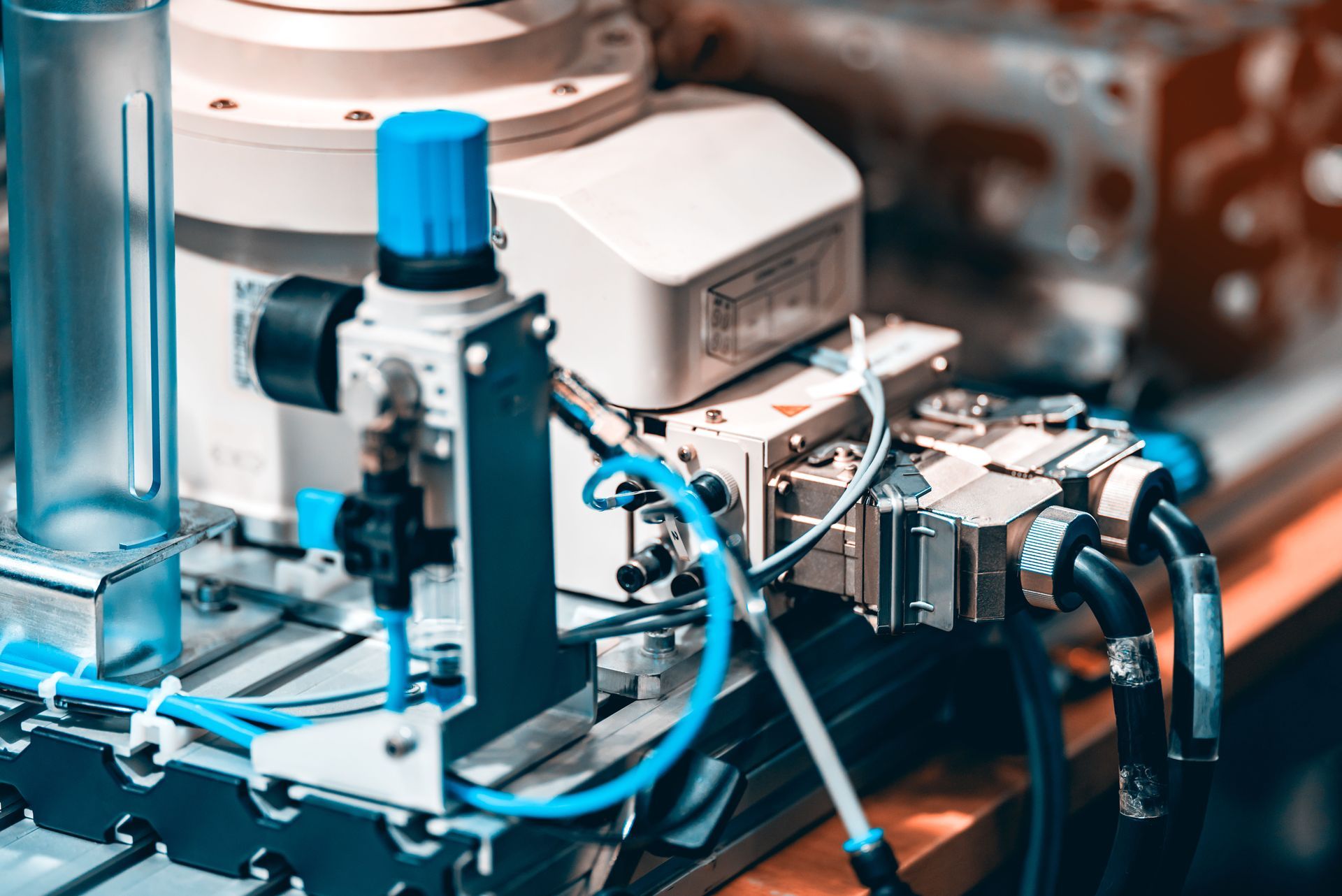

Advancing Capabilities Through Vibratory Feeder Innovations

Modern advancements in technology have also contributed to the evolving capabilities of vibratory feeders. Innovations such as programmable controls and sensors have transformed these devices into smart systems capable of self-optimization. These smart feeders can automatically adjust their settings based on real-time data, further enhancing efficiency and minimizing waste. This adaptability makes vibratory feeders a future-proof solution in the face of rapidly evolving industrial requirements.

Vibratory feeders are a vital type of bulk material handling equipment in today's automated manufacturing environments, ensuring accurate and efficient material transport. Their precision supports consistent quality and higher throughput across industries. With ongoing technological advancements and growing market demand, vibratory feeders will continue to play a key role in driving operational excellence worldwide. If you need customized and reliable material handling systems, contact Homer City Automation Inc today.

Share On: