5 Benefits of Using Rotary Feeders in Industry

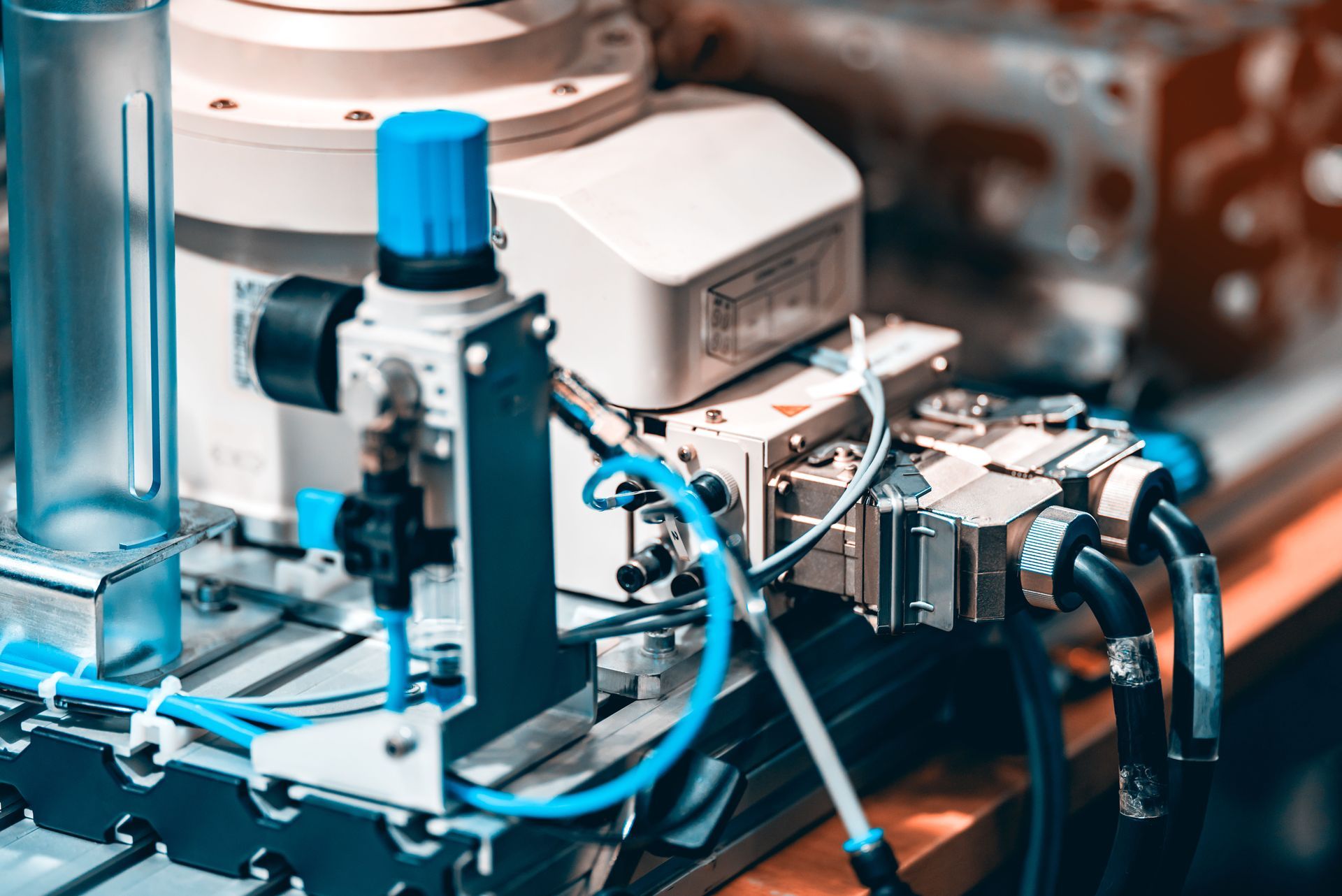

In the dynamic world of industrial manufacturing, efficiently handling and processing materials is crucial, not just for productivity but also for maintaining consistent quality. Every industry, from food production to chemicals, relies on effective material handling systems to keep operations running smoothly. One of the key elements in achieving this efficiency is the use of reliable equipment that can manage the flow of materials with precision. That is where rotary feeders come into play. These powerful devices regulate the flow of bulk materials, providing control over both the rate and consistency of discharge. They act as the backbone of many industrial processes, helping prevent disruptions and ensuring a seamless operation. You will find rotary feeders in everything from agriculture to pharmaceuticals, proving just how adaptable and essential they really are. Their ability to handle a wide range of materials, such as powders, granules, and even more abrasive substances, makes them indispensable in multiple sectors.

Let us take a closer look at some of the standout benefits of using rotary feeders in today’s industries and why they are more than just a piece of equipment. These benefits go beyond their technical specifications, highlighting how they contribute to overall operational success. Whether it is boosting efficiency, ensuring precise control, or reducing maintenance costs, rotary feeders provide a wide array of advantages that help businesses stay competitive. Understanding these benefits can help you see why investing in rotary feeders is a strategic decision for any industry looking to streamline processes and improve product quality.

1. Improve Operational Efficiency

One of the biggest perks of rotary feeders is the boost they give to operational efficiency. By maintaining a steady, controlled flow of materials, rotary feeders help reduce clogs and prevent bottlenecks. That means less downtime, fewer interruptions, and more consistent productivity. Smooth material handling also leads to lower energy consumption, which can significantly cut operational costs.

If you’ve ever dealt with the frustration of a jammed system, you’ll appreciate how much smoother things run with rotary feeders in place.

2. Handle a Wide Range of Materials

Rotary feeders stand out for their ability to handle a diverse array of materials. Whether your operation involves fine powders, rough granules, or even abrasive materials, rotary feeders can manage them all with ease.

This flexibility is especially helpful in industries that work with multiple raw material types. Instead of pausing production or changing equipment, rotary feeders support seamless transitions, reducing downtime and eliminating the need for specialized machinery.

3. Control Material Flow With Precision

Another major benefit is the level of precision rotary feeders offer in managing material flow. With adjustable speed settings and flow rates, operators can fine-tune the system to meet specific process requirements.

This control leads to better product consistency, less material waste, and overall improved process performance. In industries where accuracy matters, such as food processing or pharmaceuticals, this level of fine-tuning is a significant advantage.

4. Reflect Industry Growth and Demand

According to LinkedIn, the rotary feeders market was valued at $1.5 billion in 2022 and is expected to reach $2.5 billion by 2030. This kind of growth speaks volumes about how essential rotary feeders have become across a wide range of sectors.

As industries continue to invest in automation and efficient material handling systems, rotary feeders are taking on a larger role. Their expanding market reflects both technological advancement and growing recognition of their importance.

5. Reduce Maintenance Needs and Downtime

Rotary feeders are designed for durability and ease of maintenance. Built to withstand tough industrial environments, they require minimal servicing and have a long operational life.

This durability translates to fewer repairs, lower maintenance costs, and more reliable performance. For manufacturers, this reliability means less time troubleshooting and more time focusing on production.

Rotary feeders offer real, measurable advantages in industrial environments. From improving efficiency and handling various materials to ensuring precise flow control and minimizing maintenance, their impact is substantial. They not only enhance productivity but also contribute to long-term sustainability by reducing waste, energy consumption, and operational downtime. As industries across the globe continue to evolve and require more efficient, reliable systems, the role of rotary feeders becomes increasingly important. With demand steadily rising, now is a great time to explore how rotary feeders can support your business and optimize your manufacturing processes. Their versatility and performance make them an essential asset to any operation looking to stay ahead in a competitive market.

For expert advice and dependable solutions, contact Homer City Automation Inc and discover how the right rotary feeder can elevate your operations. With their years of experience and commitment to quality, Homer City Automation Inc can help you choose the ideal solution tailored to your specific needs. Reach out today and take the first step towards enhancing your material handling system with cutting-edge technology that drives both efficiency and reliability.

Share On: