How to Choose Manufacturing Equipment for Your Facility

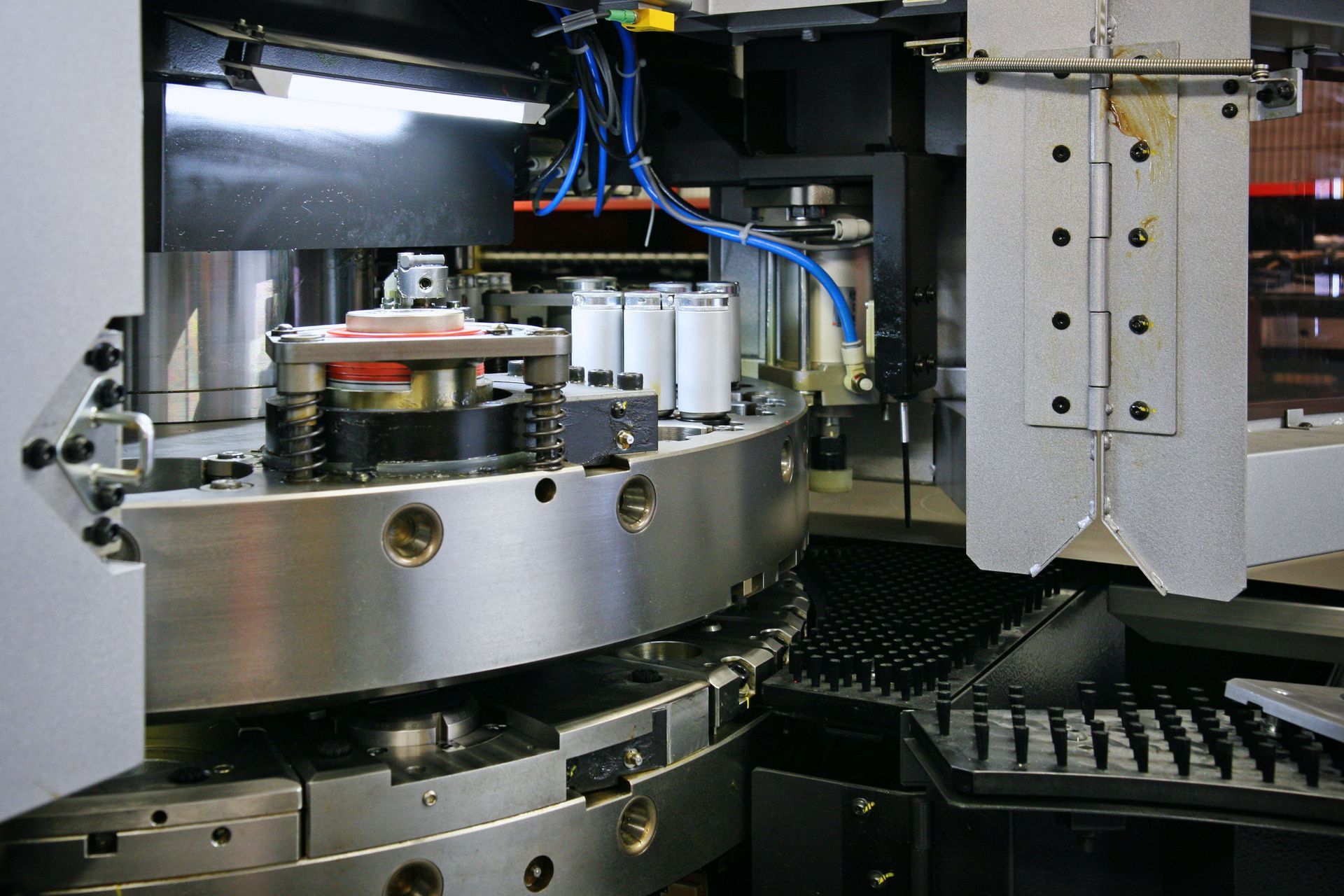

Choosing the right manufacturing equipment is a crucial decision that directly impacts the efficiency, cost, and quality of production in any facility. The range of available options, coupled with technological advancements, can make this decision quite challenging. Therefore, understanding your facility's specific needs and evaluating potential equipment based on critical insights can help you make an informed choice.

Assessing the Unique Needs of Your Facility

It's essential to assess the unique needs of your facility. This involves analyzing your production processes, identifying key bottlenecks, and understanding the scale of operations. For example, a facility with high-volume, repetitive tasks may benefit from investing in automation technologies, whereas a smaller operation might prioritize versatile, multi-functional equipment. Clearly defining your requirements helps to narrow down the plethora of choices in the market. Taking the time to evaluate these factors upfront ensures that any investment in equipment aligns with your long-term operational goals.

Researching and Evaluating Equipment Suppliers

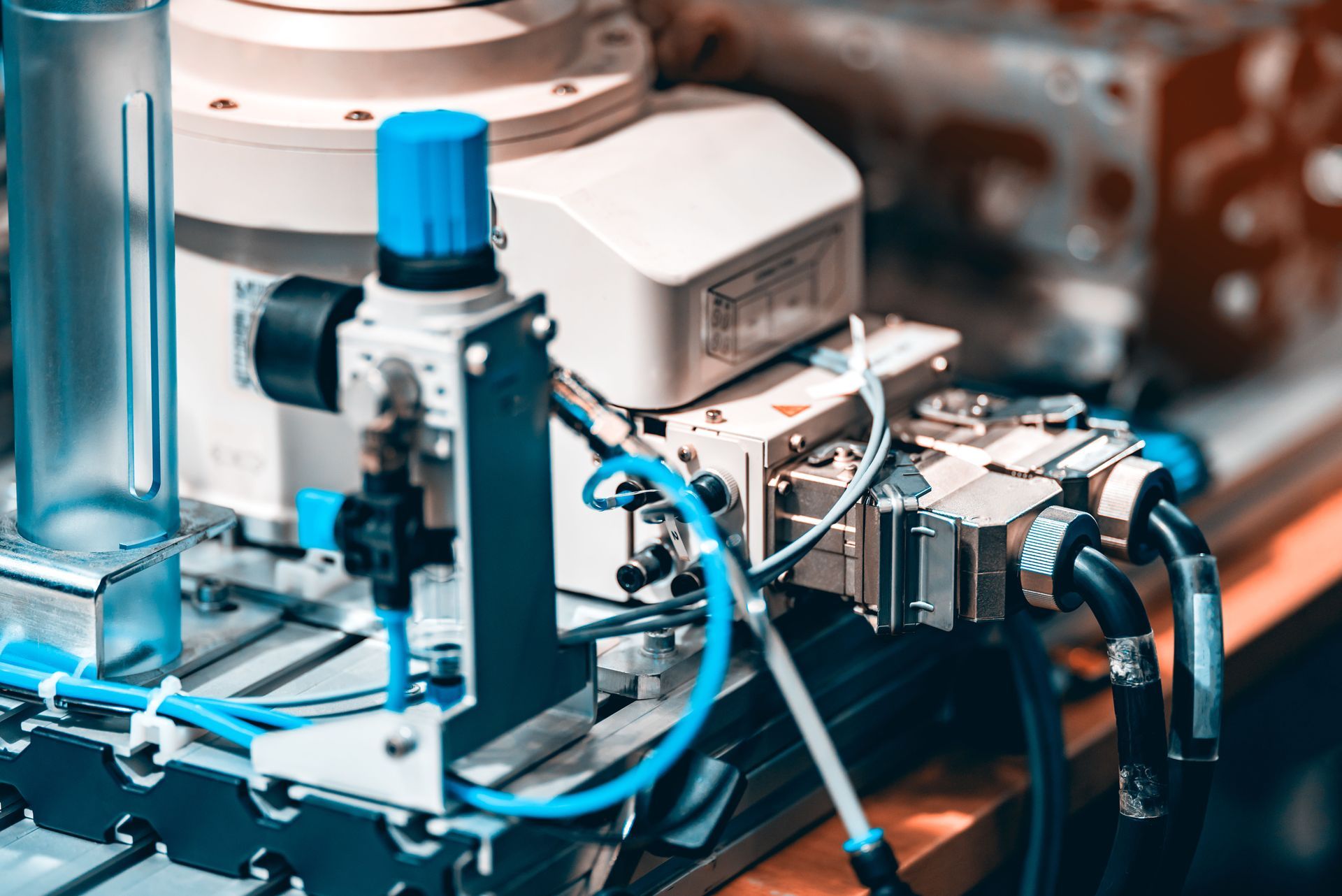

In addition to understanding your specific needs, researching the market for potential suppliers and manufacturers is also crucial. The material handling equipment manufacturing industry alone includes about 1,400 companies, according to Vertical IQ. This indicates a broad spectrum of options, each offering different levels of quality, price, and service. When evaluating suppliers, consider their industry experience, customer reviews, and after-sales support capabilities. A supplier's expertise and reliability can significantly influence the equipment's performance and your facility's operational success.

Calculating the Total Cost of Ownership

Furthermore, it is important to take into account the total cost of ownership rather than the initial purchase price alone. This encompasses maintenance costs, energy efficiency, and expected lifespan of the equipment. Investing in high-quality, durable equipment may require a larger upfront investment but can lead to savings in the long run by minimizing downtime and repair expenses. Therefore, evaluating the full scope of costs associated with each piece of equipment is imperative to making a cost-effective decision.

Choosing the right manufacturing equipment requires thorough analysis and consideration of multiple factors. By clearly defining your facility's needs, researching the market, and evaluating the total cost of ownership, you can make an informed decision that aligns with your operational and financial goals. As the manufacturing industry continues to evolve, staying informed and adaptable will be key to maintaining a competitive edge through the right equipment choices. Contact Homer City Automation Inc for more information on manufacturing equipment for your facility.

Share On: