5 Ways Bulk Material Handling Equipment Improves Safety

In industries where large volumes of materials are moved, processed, or stored, safety is always a top priority. Bulk material handling equipment plays an essential role in creating safer work environments by reducing human exposure to high-risk tasks and minimizing the potential for accidents. With continuous advancements in technology, these systems have become more reliable, automated, and safety-focused. According to Fortune Business Insights, the global material handling equipment market was valued at $239.3 billion in 2024, reflecting a growing commitment to safer industrial operations worldwide. Let's explore the ways modern bulk material handling equipment enhances workplace safety.

1. Minimizing Manual Handling Risks

Manual handling of heavy or bulky materials is one of the most common causes of workplace injuries. Bulk material handling equipment, like conveyors, hoists, and automated loaders, reduces the need for workers to lift or carry materials themselves. By taking over physically demanding tasks, these machines lower the risk of strains, sprains, and back injuries while allowing workers to operate from safer distances. This shift from manual to mechanical handling creates a safer and more controlled environment for everyone on the job site.

In addition to reducing the physical burden on employees, these systems help eliminate inconsistencies in manual movement that often lead to mishandling or dropping materials. For instance, automated conveyors move materials at consistent speeds and controlled angles, preventing the sudden shifts that can cause spills or collisions. When workers are no longer required to handle unstable loads or work in awkward postures, their risk of musculoskeletal injuries and accidents decreases dramatically. This not only safeguards their health but also promotes a stronger culture of safety awareness throughout the facility.

2. Preventing Accidents Through Automation

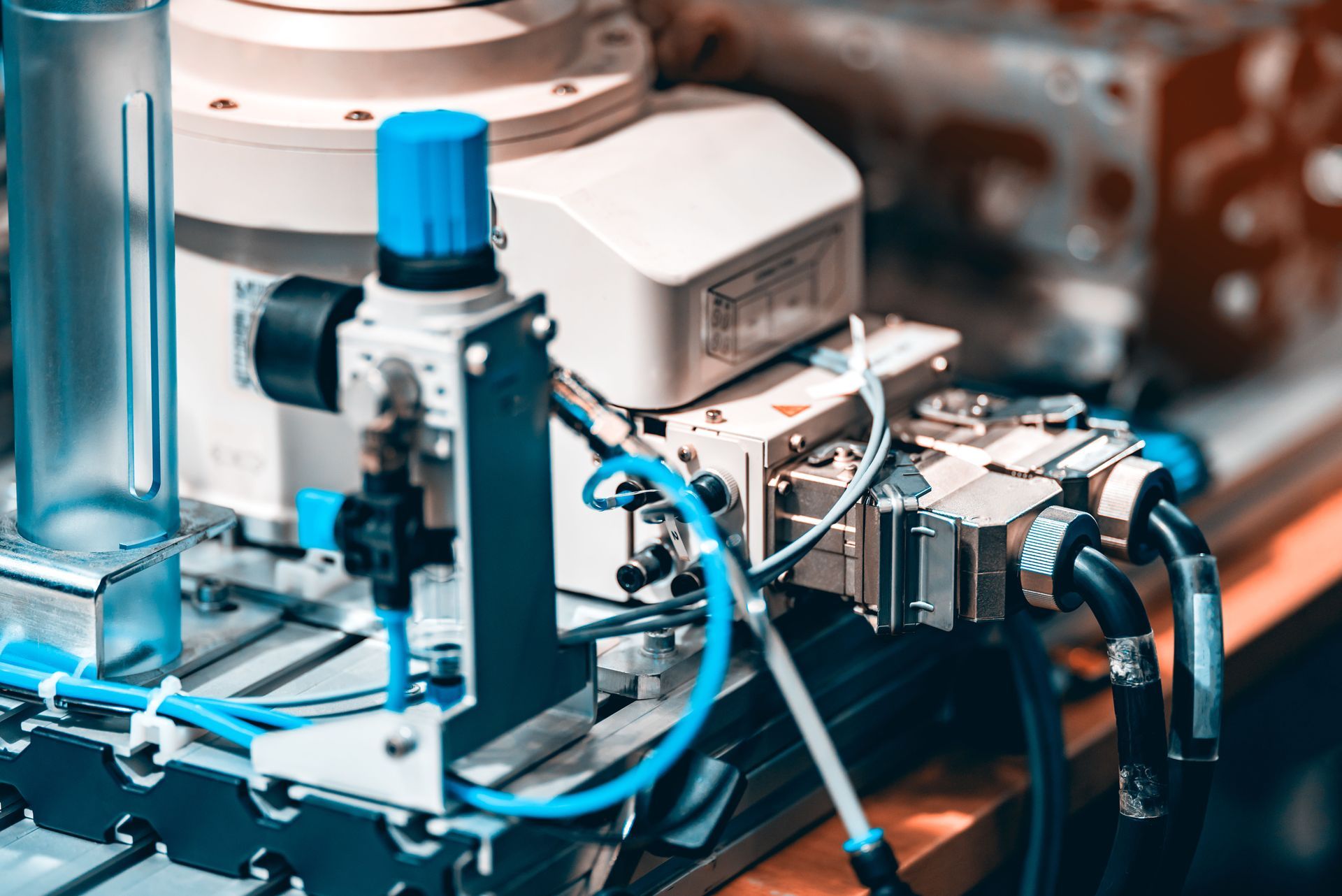

Automation is one of the most significant safety advancements in modern industrial settings. Automated material handling systems are equipped with sensors, limit switches, and emergency stop mechanisms that prevent collisions, overloads, or unsafe operating speeds. These features help eliminate the human errors often associated with fatigue or distraction. By detecting hazards in real time and shutting down operations when something goes wrong, automated systems dramatically reduce the likelihood of workplace accidents and injuries.

3. Supporting Compliance With Safety Standards

Bulk material handling equipment also helps businesses stay compliant with industry safety regulations and standards. Automated systems can be programmed to operate within strict safety limits, while built-in monitoring tools record operational data that can be used for safety audits and inspections. This not only helps companies maintain compliance with local and international workplace safety laws but also fosters a culture of accountability and continuous improvement.

Beyond meeting regulatory obligations, these systems also make it easier for companies to maintain consistent safety performance over time. Many modern handling systems include digital monitoring tools that record safety metrics such as load weight, equipment speed, and emergency stop frequency. This data allows safety managers to identify trends, schedule preventive maintenance, and adjust procedures before small issues escalate into violations or accidents. By integrating compliance tracking directly into daily operations, businesses can proactively strengthen their safety culture and reduce the risk of costly penalties or downtime.

4. Creating Controlled Work Environments

Industrial environments can be unpredictable, especially when dealing with heavy machinery and large quantities of material. Bulk material handling systems help establish control by standardizing how materials are moved and stored. Features like enclosed conveyors and dust suppression systems help reduce exposure to airborne particles or debris, while temperature and pressure controls prevent overheating or equipment failure. Together, these features contribute to a more stable and hazard-free workspace.

5. Reducing Environmental and Health Hazards

Modern bulk material handling equipment often includes design features that protect both workers and the environment. For instance, sealed transfer points prevent material spillage, and electric-powered systems reduce exposure to harmful exhaust fumes. By limiting contact with dangerous materials and minimizing pollution, these machines support long-term worker health and environmental safety. Companies adopting these technologies not only meet safety goals but also demonstrate their commitment to sustainable, responsible operations.

Safety is the cornerstone of every successful industrial operation, and bulk material handling equipment plays a key role in achieving it. From reducing manual labor risks to promoting regulatory compliance and environmental health, these systems provide layers of protection that safeguard workers and assets alike. As the global material handling equipment market continues to grow, businesses investing in these innovations are not just improving their operations; they’re building safer, more resilient workplaces for the future. Invest in safety today by reaching out to Homer City Automation Inc. We can get you started today with a free quote!

Share On: