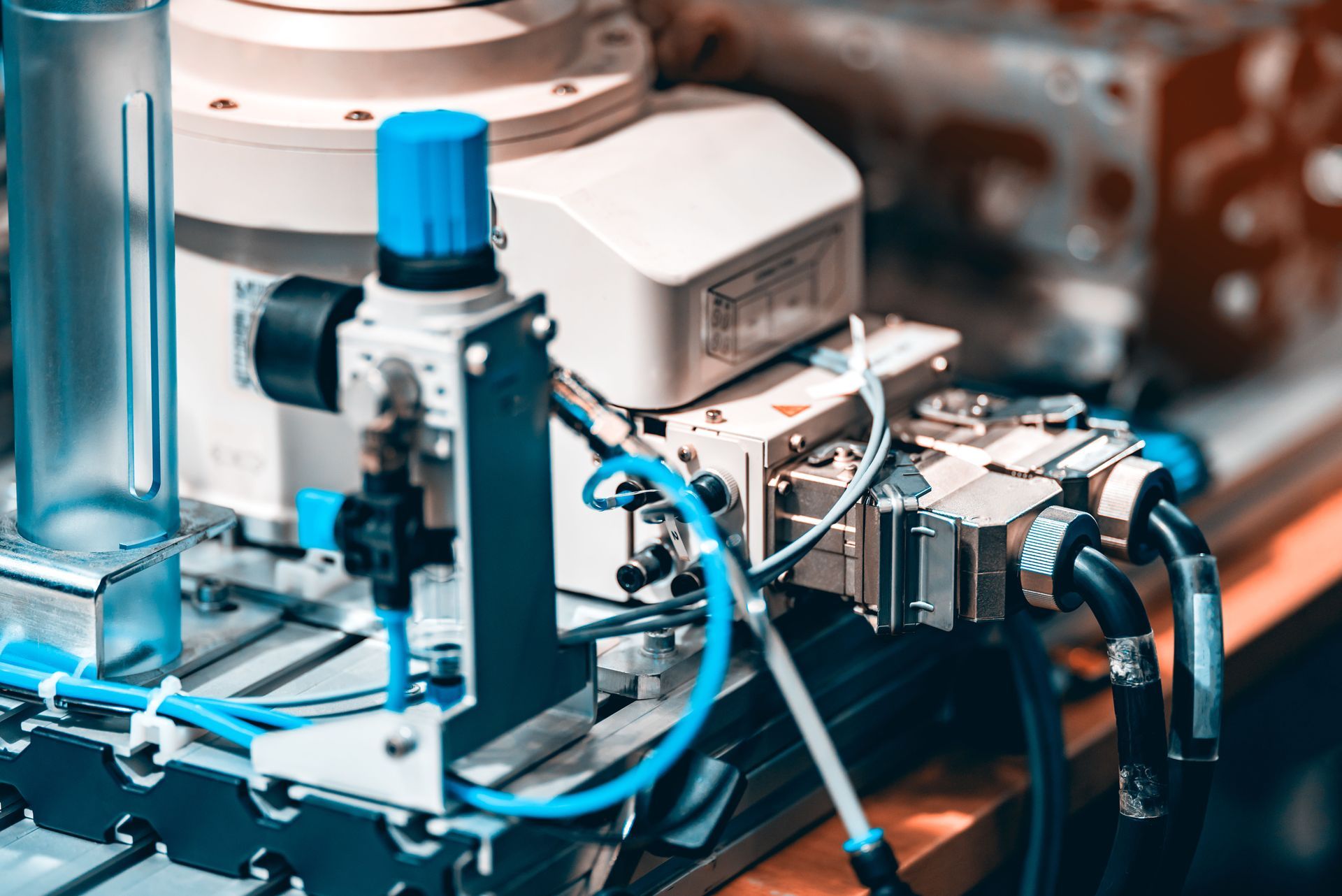

How Material Handling Equipment Improves Efficiency

Efficiency and safety are essential for maintaining a competitive edge in today's industrial landscape, and material handling equipment plays a key role in achieving both. As companies face growing demands, they rely on advanced solutions to streamline operations and reduce workplace risks. Modern systems help optimize workflow processes, allowing businesses to operate with greater precision and reliability. With these advantages, it's clear why innovative equipment has become indispensable for long-term operational success.

Enhancing Operational Efficiency with Material Handling Equipment

One of the primary benefits of material handling equipment is the significant boost in operational efficiency it provides. By automating repetitive tasks, businesses can reduce the time and labor costs associated with manual handling. This not only accelerates production lines but also allows employees to focus on more skilled tasks, ultimately increasing overall productivity. Furthermore, advances in technology have led to sophisticated machinery that can handle materials with precision, thereby reducing waste and optimizing resource use.

Improving Workplace Safety Through Advanced Handling Technology

Efficiency through safety is another critical consideration that material handling equipment addresses effectively. Traditional methods of moving heavy loads can pose significant risks, including injury to workers and damage to products, which can reduce workload significantly. By employing equipment such as forklifts, conveyors, and automated guided vehicles, companies can mitigate these risks significantly. According to Arizton, the U.S. construction equipment market is expected to reach 486,000 units by 2029, indicating a rising trend in the adoption of such technology. This growth underscores the industry's commitment to safer and more efficient material handling solutions.

Strengthening Inventory Management and Logistics with Automated Systems

The integration of modern material handling systems also leads to improved inventory management and logistics. Automated systems provide real-time data and analytics that enable better tracking and control of inventory levels, reducing the risk of stockouts or overstocking. These systems improve accuracy in order fulfillment and reduce lead times, which in turn enhances customer satisfaction. As businesses expand and their operations become more complex, the need for reliable material handling solutions becomes even more critical.

Material handling equipment is crucial for any business aiming to improve efficiency in their operations. By automating processes and integrating advanced technology, companies can reduce labor costs, increase productivity, and minimize risks. If you need customized material handling equipment that will give your business a competitive edge, contact Homer City Automation Inc today.

Share On: