5 Ways to Improve Efficiency with Bulk Material Handling Equipment

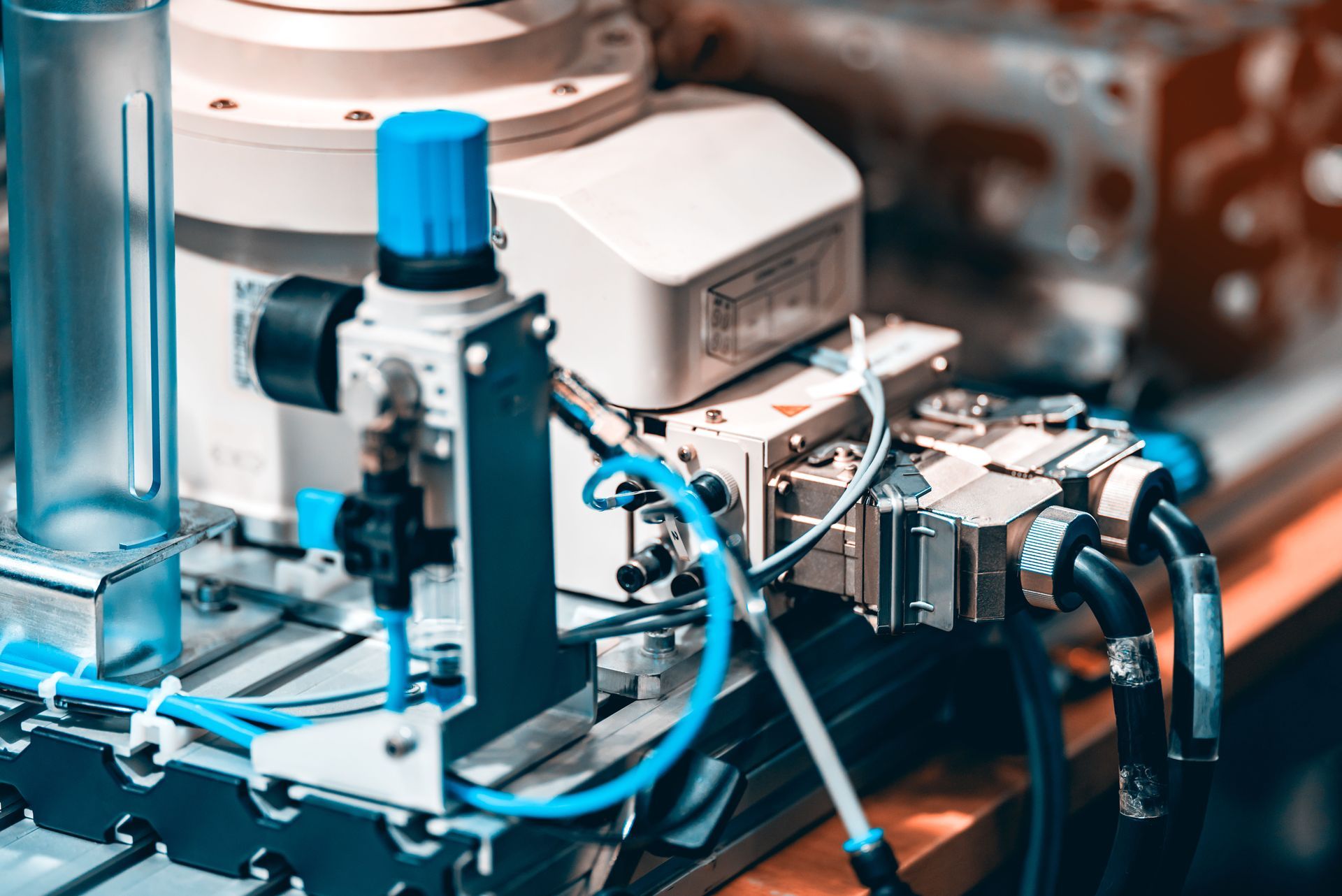

In today’s fast-paced industrial environment, efficiency is essential for productivity and profitability. Businesses that handle large quantities of raw materials rely heavily on bulk material handling equipment to streamline operations, reduce costs, and maintain a smooth workflow. Proper utilization of these systems can make the difference between a facility that runs at peak performance and one plagued by delays, downtime, and inefficiency.

From conveyors and belt bucket elevators to hoppers and feeders, the right bulk material handling equipment ensures that materials move safely and efficiently through the production process. In this article, we explore actionable strategies to enhance operational efficiency, prolong equipment life, and maximize the return on your investments.

1. Utilize Advanced Technology

Integrating advanced technology into bulk material handling equipment is one of the most effective ways to boost efficiency. Automation, such as programmable logic controllers (PLCs) and conveyor control systems, reduces the need for manual intervention and accelerates material flow. These systems allow operators to manage complex processes with minimal error, improving throughput and consistency.

The incorporation of IoT sensors adds another layer of efficiency. These sensors provide real-time data on equipment performance, including vibration, temperature, and operational speed. By monitoring machinery continuously, companies can detect early signs of wear or malfunction, allowing for predictive maintenance that prevents unexpected downtime. Adopting these technologies ensures your bulk material handling equipment operates at peak performance, reducing bottlenecks and improving overall workflow.

2. Invest in High-Quality Equipment

The quality of your bulk material handling equipment directly impacts operational efficiency. Durable, high-performance machinery withstands heavy use while minimizing breakdowns and maintenance needs. Investing in reliable equipment translates to fewer interruptions and a smoother production process, ultimately boosting profitability.

For example, the belt bucket elevator market, projected to reach around $2.5 Billion by 2033 according to Data Horizon Research, highlights the demand for efficient, long-lasting material handling solutions. Facilities that invest in premium conveyors, elevators, and feeders can expect not only higher throughput but also long-term cost savings by reducing frequent repairs and replacements. Prioritizing quality in bulk material handling equipment is a strategic decision that pays dividends in operational efficiency.

3. Optimize Layout and Workflow

Efficiency is not only about machinery—it’s also about how materials move through your facility. Optimizing layout and workflow can significantly reduce handling time and increase productivity. Proper placement of bulk material handling equipment minimizes unnecessary movement, reduces congestion, and ensures that material flow is smooth from receiving to processing.

Conducting a process audit can identify bottlenecks and inefficiencies in your operations. Implementing a lean manufacturing approach ensures that every step adds value and eliminates wasted motion. Even minor adjustments to equipment placement, conveyor angles, or feeder positioning can create measurable gains in efficiency. By optimizing both layout and workflow, your bulk material handling equipment can operate at maximum capacity with minimal disruption.

4. Implement Regular Maintenance Schedules

Routine maintenance is essential for sustaining the efficiency of bulk material handling equipment. Machinery that is well-maintained runs more reliably, reducing unplanned downtime and costly repairs. Developing a structured maintenance schedule allows operators to inspect, lubricate, and replace worn components proactively.

Preventive maintenance extends the lifespan of conveyors, elevators, and other material handling systems while maintaining peak performance. For example, checking belts for wear, cleaning dust and debris from hoppers, and verifying motor alignment can prevent small issues from escalating into major failures. Regular attention to maintenance ensures that your bulk material handling equipment continues to operate safely and efficiently, protecting both production and personnel.

5. Train Employees Effectively

Even the most advanced bulk material handling equipment requires skilled operators to achieve maximum efficiency. Comprehensive training programs are essential to ensure employees can use, maintain, and troubleshoot machinery effectively.

Training should cover operational procedures, safety protocols, and basic maintenance routines. Employees familiar with the nuances of conveyors, feeders, and elevators are less likely to cause operational disruptions or incur repair costs due to improper handling. Additionally, well-trained staff can identify early signs of equipment strain, reporting issues before they escalate. Fostering a knowledgeable workforce helps your bulk material handling equipment perform at its best while promoting a safe, productive environment.

Improving efficiency with bulk material handling equipment requires a comprehensive approach. By integrating advanced technology, investing in high-quality machinery, optimizing layout, scheduling regular maintenance, training employees, and monitoring performance, businesses can maximize productivity and minimize downtime.

For businesses seeking expert guidance and solutions for

bulk material handling equipment, Homer City Automation Inc provides specialized support and cutting-edge systems tailored to your operational needs. Contact us today to enhance efficiency and achieve seamless material handling in your facility.

Share On: